Manufacturing in transition - the transition to Industry 4.0

Today, the industrial manufacture of products in large quantities is carried out using special machines and highly automated production and assembly lines. For small quantities or even one-offs, on the other hand, a high degree of automation is not yet economical and cost-intensive manual work predominates. However, a profound change is currently taking place here. Using the latest information technologies, intelligent networked systems are being developed for Industry 4.0, which will enable close communication between people, machines, components and parts in the near future and will lead to a level of flexibility in production that is almost unimaginable today.

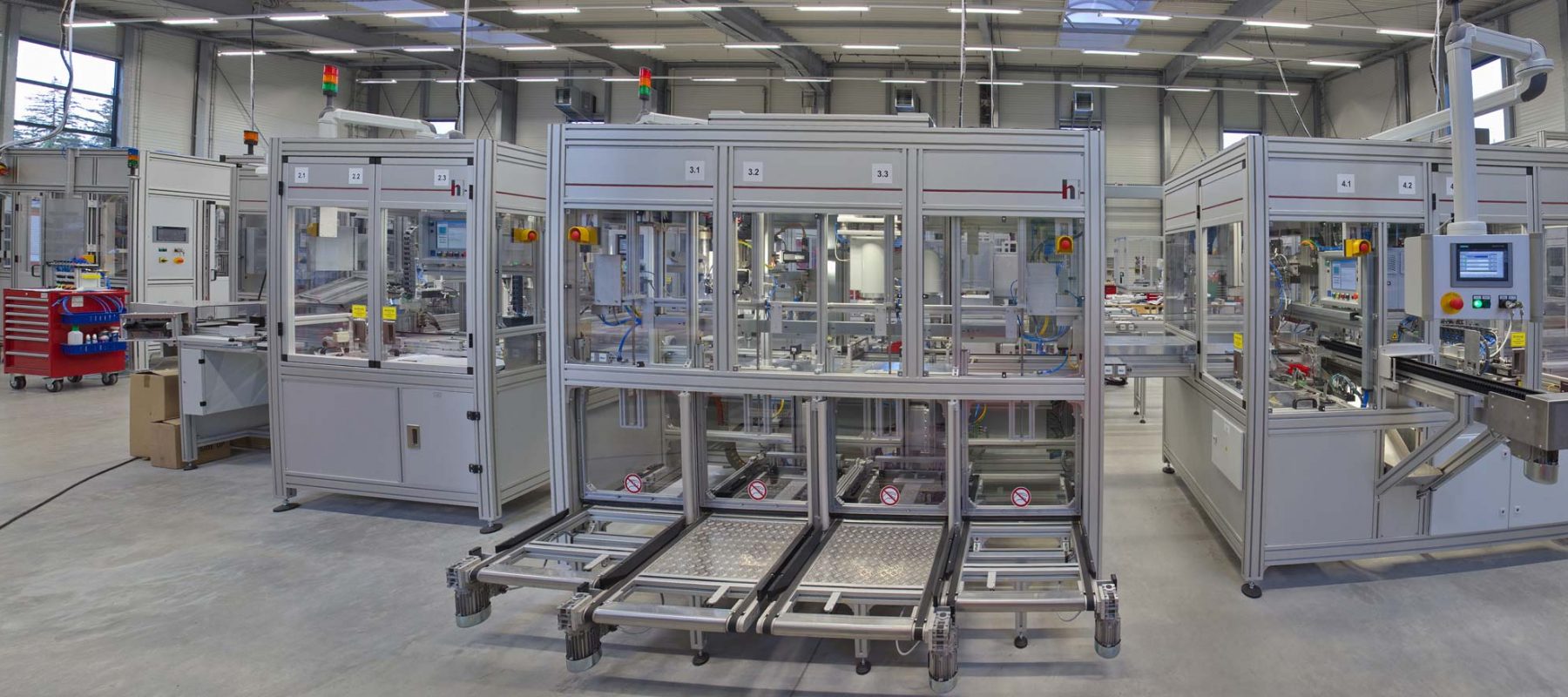

HENKEL + ROTH, a pioneer in automated assembly

Years before the term Industry 4.0 was introduced to the public at the Hanover Fair in 2011, the engineers at HENKEL + ROTH began developing the mobile robot.

This revolutionary system embodied important basic ideas of the Industry 4.0 concept and, when it was presented at MOTEK 2008, was the world's first mobile industrial robot that could be flexibly integrated into existing assembly lines as required and without significant effort in order to perform a wide range of handling and assembly tasks. Since then, developers and engineers at HENKEL + ROTH have been working flat out to design new systems for you in the era of Industry 4.0.

Current work at HENKEL + ROTH on Industry 4.0 and Assembly 4.0

Aktuelle Arbeiten bei HENKEL + ROTH zu Industrie 4.0 und Montage 4.0

5-side automatic assembly machine 4.0

- Further development of the established 5-side automatic assembly machine to meet the requirements of Industry 4.0

- Expansion of the range of available processing options and combination with alternative processes such as ultrasonic welding

mobile robot

- Development of the third generation of the mobile robot

- Cooperation with the TU Ilmenau and regional robotics companies

Universal workstation with intelligent interchangeable plates

- Realization of a variable system with short set-up times that can take on assembly tasks ranging from weakly automated assembly to highly integrated robot technologies

- Integration of intelligent changing devices

Joint project freeMoVe

- Development of a system for versatile assembly in freely networked assembly systems based on the mobile robot

- Collaboration with RWTH Aachen University and industrial partners, funded by the BMBF

Flexible robot-assisted assembly cell

- Design of a flexible robot-assisted assembly cell with adaptive safety zone for active human-machine collaboration

- Focus on small and very small quantities in assembly

3D printing in assembly

- Analysis of the potential of 3D printing in special machine construction with a focus on assembly technology

- Cooperation with the TU Ilmenu