Joint project KOMERO

Safe collaboration between humans and robots in the joint assembly of products

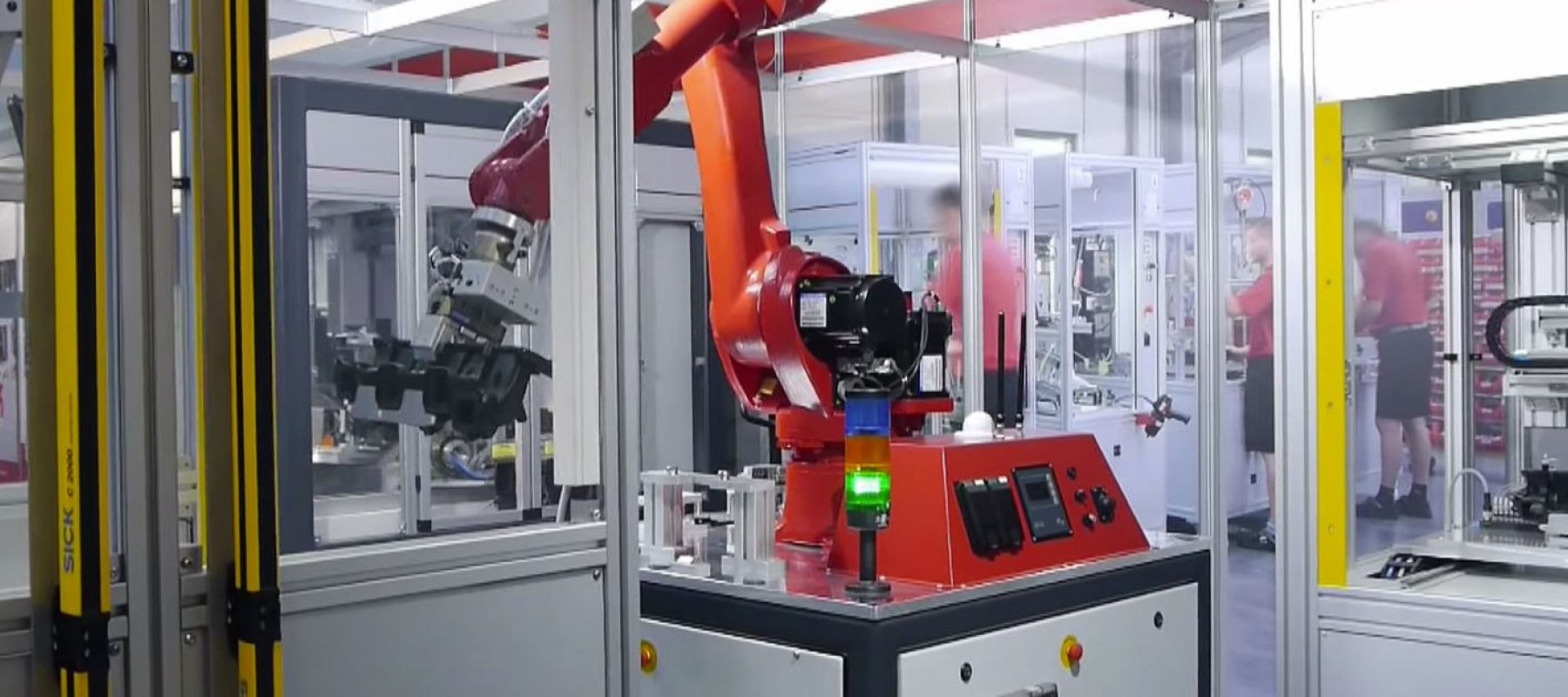

Safety plays a key role when humans and robots work together in confined spaces. In the KOMERO project, the Fraunhofer Institute for Applied Optics and Precision Engineering IOF and HENKEL + ROTH are working together to develop a flexible robot-supported assembly cell with an adaptive safety zone for active collaboration between humans and robots with flexible and variable assembly processes. Various work steps are to be carried out alternately by humans and robots, and this for small quantities during assembly, so that it is possible to switch quickly from one component to be assembled to another. One of HENKEL + ROTH's tasks is to combine the haptic and optical capabilities of humans with the reproducibility and speed of robots to create a solution that is more flexible, cheaper, faster and more reliable than humans or robots alone

Objectives:

The aim of the project is to develop a flexible, robot-supported assembly cell with an adaptive safety zone for active collaboration between humans and robots with flexible and variable assembly processes.

Various work steps are to be carried out alternately by humans and robots for small assembly quantities, so that it is possible to switch quickly from one component to be assembled to another. One task of the sub-project is to combine the haptic / optical capabilities of humans with the reproducibility and speed of the robot to create a solution that is more flexible, cheaper, faster and reproducible.

Project duration from 01.03.2018 to 30.09.202

Joint project freeMoVe

Versatile assembly in freely networked assembly systems

The freeMoVe project is funded by the BMBF (Federal Ministry of Education and Research). It is embedded in the BMBF program "Innovations for the production, services and work of tomorrow" and is supervised by PTKA (Project Management Agency Forschungszentrum Karlsruhe).

The project partners are Infineon AG, ZF, ABB, PHOENIX CONTACT, Philips, IFSYS Integrated Feeding Systems, the ZIMMER Group, WZL, RWTH Aachen University, the Fraunhofer IPT and HENKEL + ROTH.

The aim of freeMoVe is to develop a new form of organization for versatile, highly variant assembly for small quantities down to batch size 1. To this end, the project partners are developing the planning, control and information provision for assembly and the necessary versatile technology.

As part of the project objective, HENKEL + ROTH is developing a mobile robot based on the mobile robot that can freely network the material flow in industrial applications.

Projektlaufzeit 01.01.2017-31.12.2019

Internal project Industry 4.0

HENKEL + ROTH already offers its customers special machines, automatic assembly machines and robots that have been developed to meet the requirements of Industry 4.0. As Industry 4.0 is not a static system, but on the contrary is developing extremely dynamically, the developers and engineers at HENKEL + ROTH are constantly working on the further development and improvement of its products. Objectives of the internal Industry 4.0 project:

- Further development of the intelligent assembly device project with integrated control for storing product-specific parameters

- Design of the intelligent devices for use on the 5-side automatic assembly machine in combination with mobile robot

- Networking of special machines

- Further development of the database connection for intelligent data evaluation (data tracking for quality control and process optimization)

- Self-learning assembly machines that optimize their process parameters to ensure product quality (in future also without a setter)

- Self-monitoring machines and devices that monitor wear and automatically order maintenance depending on the frequency of use

- Marketing strategy with basic "4.0 ready" machine equipment and selectable software functions in line with the above-mentioned development goals

Further information on the project:

Internes Projekt mobile robot

With the second-generation mobile robot, HENKEL + ROTH offers a self-contained system that can be used for a wide range of handling and assembly tasks as required. The mobile robot 2.0 represents the integration of a high-performance industrial robot into an autonomous platform and offers a significantly greater range and a broader spectrum of tasks than a classic industrial robot.

Objectives of the internal mobile robot development project:

- Further development of the mobile robot to Generation 3.0

- Collaboration with the TU Ilmenau and regional robotics companies

- Creation of an industrial application for flexible use in production Market launch of the mobile robot 3.0

- Strategy for marketing the mobile robot 3.0 in combination with the entire technical periphery in a complete package (mobile robot, safety technology, material supply, interfaces to machines)

Further information on the project:

Internal project 5-sided automatic assembly machine

With its 5-sided automatic assembly machine, HENKEL + ROTH already offers its customers a system that can be easily adapted to a wide range of assembly technologies and thus enables the assembly of a large variety of customer parts.

Objectives of the internal 5-sided automatic assembly machine project:

- Further development of the established 5-sided automatic assembly machine for the constantly changing requirements of the Industry 4.0 era.

- Customer survey on the future requirements of flexible assembly machines.

- Expansion of the machine's application options by integrating alternative processes such as ultrasonic welding etc.

- Combination of the 5-sided automatic assembly machine with the mobile robot.

Further information on the project:

Internal project Universal workstation with intelligent removable trays

The universal assembly workstation is used for the semi-automatic processing of components. The scalable frame concept integrates various safety systems for occupational safety and can be ergonomically adapted to assembly requirements thanks to the height-adjustable platform. The intelligence and technology is located on the changing devices. With short set-up times, a wide range of tasks can be covered, from lightly automated assembly tasks to highly integrated robot technologies.

Internal project 3D printing in assembly

HENKEL + ROTH is convinced that 3D printing will also play an important role in assembly technology. The internal visionary project 3D printing in assembly takes this into account.

Aims of the project:

- Research into the potential of 3D printing for special machine construction with a focus on assembly technology

- Investigations into the production of complex fixture components using 3D printing

- Analysis of 3D printing as a generative process in assembly

- Cooperation with the TU Ilmenau, Faculty of Mechanical Engineering, Department of Production Engineering

- Assignment and supervision of a student research topic on 3D printing in assembly

Internal project Promoting energy efficiency in the company

The conservation of natural resources during production and low energy consumption during operation are important internal assessment criteria for HENKEL + ROTH products. Saving energy is also high on the agenda within the company itself. To this end, HENKEL + ROTH has been working on increasing energy efficiency and the increased use of renewable energies in a project funded by the Free State of Thuringia and the EU.

Consulting in the company

Energy situation analysis and specification of targets and measures to increase energy efficiency in future investments.

Investments in the company

- Optimization of the compressed air system

- Energy-efficient LED lighting in production hall 4

- Optimization of night cooling through air circulation in the ventilation system

- Optimization of the cold water cassettes