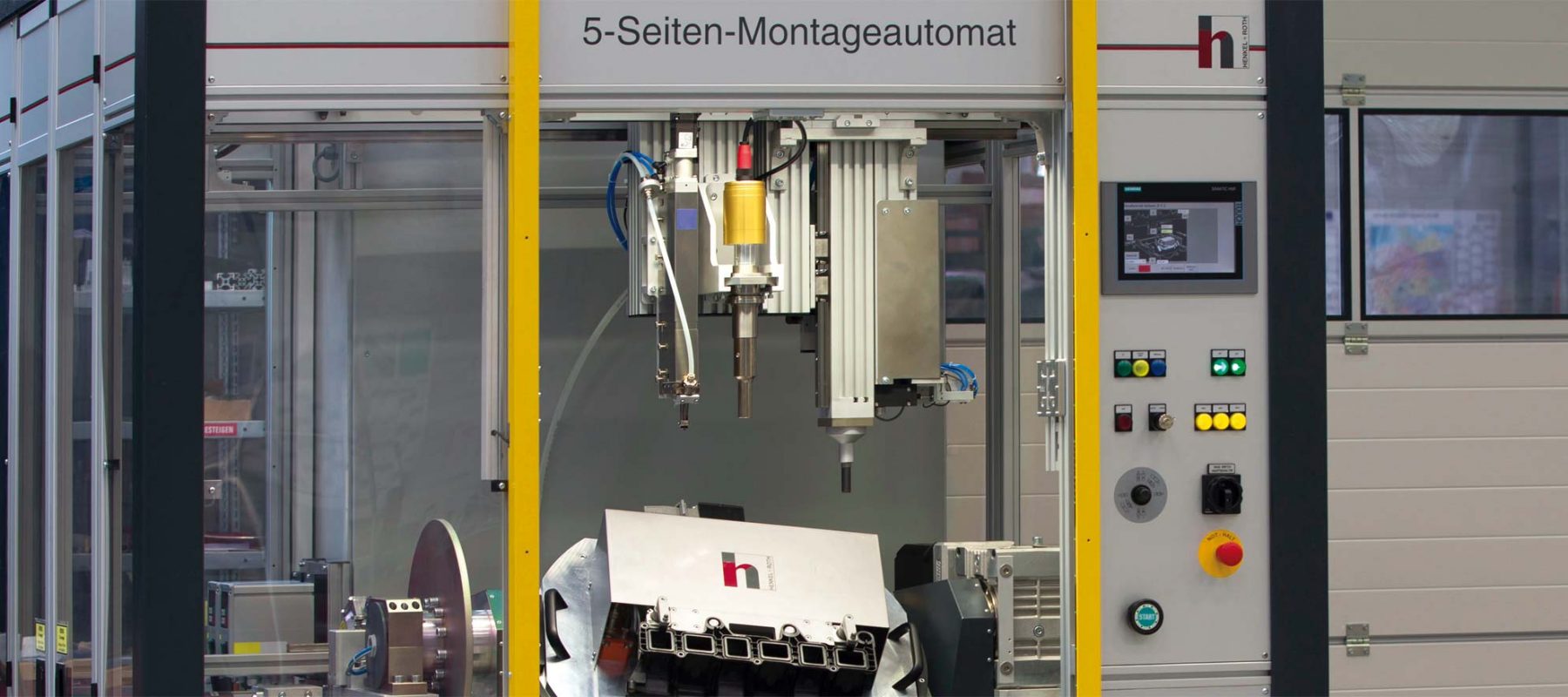

Automatic 5-side assembly in one clamping operation

With a single flexible, compact and user-friendly system, different assembly work can be carried out from five sides in a single clamping operation. This enables greater precision and speed thanks to fewer reclamping operations and more freedom in design.

Everything in one clamping operation, such as joining, screwing, riveting, gluing, testing or measuring, is possible in five-sided machining with our automatic assembly machine.

The machine works faster, more precisely and takes up less space than a robot with comparable capabilities. It can be intuitively converted to new processing programs without a great deal of programming effort and is therefore particularly suitable for the production of various medium-sized components in small batches.

„We are rethinking - from 'assembly-compatible design', which is often almost impossible to achieve perfectly in practice, to construction-compatible assembly.“Matthias Roth, managing director

5-sided automatic assembly machine - Technological details

- Flexible and compact machine for 5-sided assembly

- Assembly of the workpiece in just one clamping operation

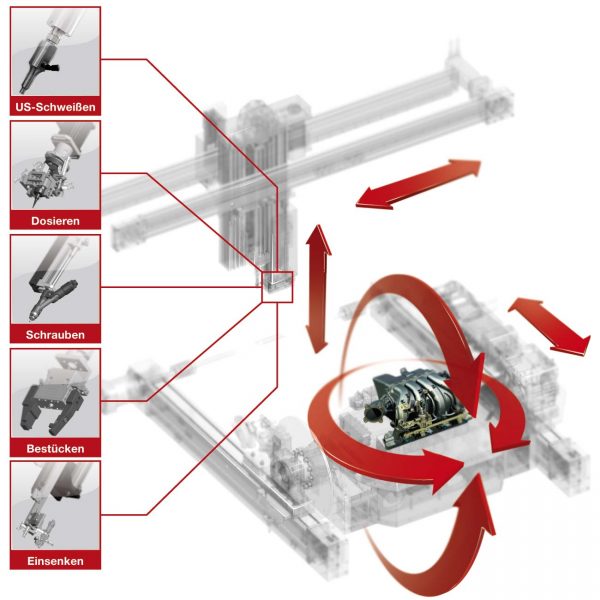

- Minimization of reclamping processes, reduction of auxiliary times by rotating the workpiece with the clamping device

- Integration of different assembly processes, e.g. screwing, joining, countersinking, riveting, gluing, ultrasonic and spot welding and other assembly technologies

- High machining forces without sacrificing precision

- Quick and flexible changeover thanks to interchangeable holders

- Ideal for small batches with many workpiece and product variations

- Easy operation thanks to convenient user-oriented menu navigation via touch screen and access to process parameters in a database

- Manual or fully automatic insertion and removal of workpieces, e.g. by mobile robot

Technical data

Status 03/2017

Electrical connection

| Voltage: | 400V 3~ /N/PE, 50-60Hz | |

| Connection: | CEE-plug 400V / 32A | |

| Nominal power: | 10 kVA | |

| Protection class: | IP 54 |

Pneumatic connection

| Quick-release coupling: | NW 7,8 | |

| Compressed air connection: | > 6 to 10 bar, unlubricated, filtered | |

| Working pressure: | 6 bar | |

| Peak consumption: | approx. 150 l/min |

Dimensions:

| Dimensions (WxHxD): | 2.220 x 2.300 x 2.100 mm | |

| Weight | approx. 1.500 kg | |

| Servoachsen: | Travel | Speed |

| X-axis (double toothed belt axis for machine table with interchangeable holder) | 650 mm | 1.300 mm/s |

| Y-axis (toothed belt axis for single countersunk head) | 1.150 mm | 1.500 mm/s |

| Z1 axis / optional Z2 axis (spindle axis for single countersunk head) | 410 mm | 1.500 mm/s |

| A-axis (pivot axis) | ± 110° | 250 grd/s |

| C-axis (rotary table for holding the changing device) | ± 185° | 340 grd/s |

5-side countersinking machine

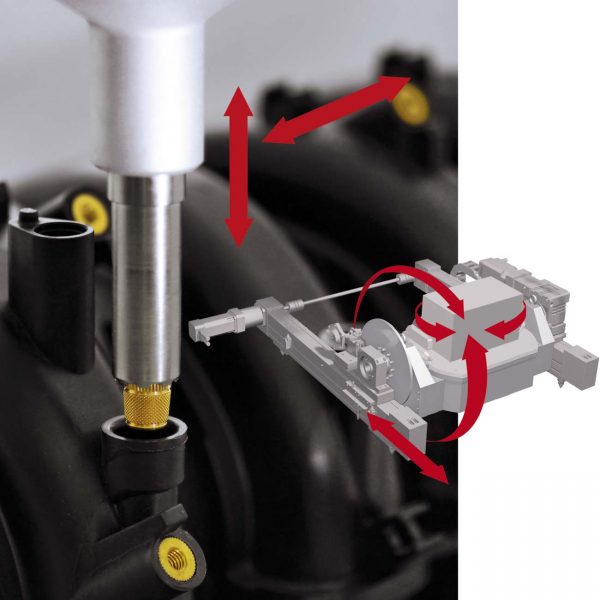

The hot countersinking of metal threaded bushes into plastic parts is now also possible in five-axis machining.

The automatic assembly machine developed by HENKEL + ROTH combines the faster and more precise five-sided machining that was first realized for this requirement with a new concept for separating, heating and controlled countersinking of different insert types.

5-axis countersinking machine - technological details

- Automatic machine for flexible hot countersinking of threaded bushes in plastic parts (e.g. intake manifolds, cylinder head covers, cladding parts, housings, etc.)

- 5-sided machining of plastic parts with 5 servo axes requires fewer reclamping operations and increases productivity

- Countersinking of different bushes is optionally possible (e.g. with different thread diameters)

- Innovative arrangement for separating with variable heating for each individual bushing using high-frequency technology

- Controlled countersinking of the bushings to a target dimension in relation to the circumferential bore edge on the plastic part with an accuracy of ± 0.05 mm

- Special countersinking head with floating bearing of the bushes to compensate for position tolerances of the holes

- Convenient operation thanks to intuitive menu navigation (touch screen)

- Database query of type-dependent process parameters

- Insertion and removal of workpieces manually or fully automatically by gantry robot or mobile robot

Wide range of automation options

Decisive rationalization advantages can also be achieved with the five-axis hot-inserting machine from HENKEL + ROTH GmbH thanks to a wide range of additional automation options. Minimal cycle times are possible by optimizing the holding and air-assisted cooling of the bushings after countersinking; the conveyor system for the inserts can be refilled without stopping the automatic system. The workpieces can be inserted and removed either manually or fully automatically in conjunction with a stationary or mobile robot.

The clamping system works with self-identifying interchangeable plates for the different plastic parts. This means that the machine can be converted to a new workpiece type very quickly. Depending on which part type the system has identified, the position data for the insertion head and bushing handling is loaded from a database in which the type-specific process parameters are stored. Another plus point is the convenient operation thanks to user-friendly menu navigation via touch screen. The robust design of the system, which is built on a sturdy steel frame, safely absorbs static and dynamic loads. Thanks to its compact architecture with integrated control cabinet, the HENKEL+ROTH automatic assembly machine can be easily integrated into the process chain of any plastics processor who wants to benefit from the time and precision advantages of flexible bushing hot countersinking in five processing dimensions in times of constantly increasing cost and deadline pressure.

Technical data

status 03/2017

Electrical connection:

| Voltage: | 400V 3~ /N/PE, 50-60Hz | |

| Connection: | CEE-plug 400V / 32A | |

| Nominal power: | 10 kVA | |

| Protection class: | IP 54 |

Pneumatic connection

| Quick-release coupling: | NW 7,8 | |

| Compressed air connection: | > 6 to 10 bar, unlubricated, filtered | |

| Operating pressure: | 6 bar | |

| Peak consumption: | approx. 150 l/min |

Dimensions

| Dimensions (WxHxD): | 2.220 x 2.300 x 2.100 mm | |

| Weight: | approx. 1.500 kg | |

| Servo axis: | Travel | Speed |

| X-axis (double toothed belt axis for machine table with interchangeable holder) | 650 mm | 1.300 mm/s |

| Y-axis (toothed belt axis for single countersunk head) | 1.150 mm | 1.500 mm/s |

| Z1 axis / optional Z2 axis (spindle axis for single countersunk head) | 410 mm | 1.500 mm/s |

| A-axis (pivot axis) | ± 110° | 250 grd/s |

| C-axis (rotary table for holding the changing device) | ± 185° | 340 grd/s |